We have a client who hired the wrong person to re-build and cap some large outrigger beams on their house in Berkeley.

The results were devastating. All the beams rotted fully into the inside walls, leaving the roof ‘floating’ without support.

Both aluminum and pure zinc corrode rapidly when standing water, or salts are present.

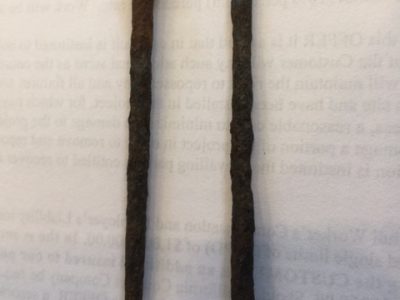

Remember looking at old barns and seeing the wood rotted away around rusty nails? Moisture condenses in the wood interior every night. If the nails are not hot dipped in galvanizing, they will rust away. Iron fixating bacteria will eat the rusty wood, until it disappears. The same thing happens to wood windows, particularly open celled wood like pine. We have seen many commercial wood windows rot away from the inside.

A consulting client who fabricated and installed 24 stories of powdered coated aluminum. The powder coating company cleaned the newly fabricated rails with tap water, leaving chlorine salts behind. They did not prime, only applied one coat without a clear finish sealer. The rails all 24 floors turned to aluminum oxide (like foam) under the paint and disintegrated.

So powder coating is not a miracle, particularly when standards are not followed.

Decks leak commonly because galvanized metal flashing corrodes away if not fully water sealed with epoxy, the rubber, generally in less than 5 years.

So beware of contractors and designers who are agnostic and don’t believe in what they can’t see. Gravity is invisible, but mighty effective! It is not who you know, but who you know, who knows!